As a lubricant, Gilsonite is used in glue and sealants. The material is used to obtain a variety of products when combined with other chemicals. Binder and coating applications in metallurgical, wood products, refractory and other industries further demonstrate the versatility and usefulness of this remarkable material.This material is a non-toxic, non- carcinogenic and cost-effective replacement for natural rubber. Gilsonite is used as a solidifying agent in metal alloys. This material has a high carbon percentage which creates a reductive environment when added to melted steel. In shaping metals, Gilsonite is again used as a solidifying agent.

Moreover, compared to other polymers, Gilsonite produces less smoke in high temperatures. Gilsonite as a solidifying and mixing material is used in steel desulfurization process. This material has volatile ingredients which facilitate the mixing of desulfurization chemical materials such as magnesium and hydrated lime. Moreover, it increases the percentage of the carbon added to steel and as soon as oxidation happens in high temperature, it creates a reductive environment. In manufacturing of products such as clutch plates and brake parts is used using Gilsonite which is basically as a solidifying agent. This material is also used as an additive for increasing paint’s shade and in some cases for reducing friction.

In the wood and carpentry industry, Gilsonite is used as a solidifying agent (glue). This material is water proof and corrosion resistant. Gilsonite is used as insulated coatings for pipes. This material is a nontoxic gum with excellent adhesiveness. Anti-corrosion coatings which are chemically ineat can be produced from Gilsonite.

Some uses of Gilsonite in chemicals:

- In ceramic production

- In rubber industry

- In wood industry

- In steel product

-

Gilsonite in ceramic production

Ceramics can be defined as non-metallic mineral materials. The Obsidian rock that forms from the molten crystallization is an example of ceramics that naturally occur. While advanced ceramics are created by the natural ceramics. Advanced ceramics are used as substrates in household chips, refractories, capacitors, wireless communications, electrical and thermal insulators.

Unlike metals, ceramics have low thermal and electrical conductivity and are hard and firm in terms of mechanical properties, but are very fragile and have a low resistance to impact. Ceramics have a special strength against compressive strength. Ceramic parts are produced after a series of preparation operations on raw materials are produced. Today, with the help of advanced processes, specialists are able to produce ceramic with a shock-proof impact. These improvements have made it possible for ceramics to be used in applications that need to withstand different forces. Adding Gilsonite to ceramic leads to adhesion between ceramic materials at low temperatures.

-

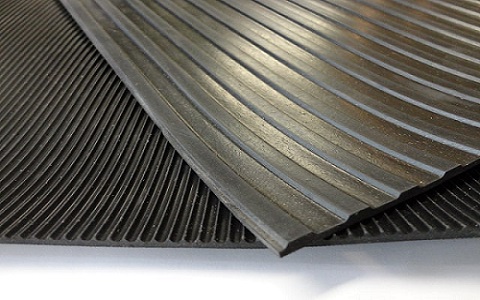

Gilsonite in rubber industry

Because of the presence of sulphur in the bitumen, the band that creates the molecule is 8-fold and reduces rupture, which is very important for rubber production. This additive makes it superbly bonded, and even after mixing with bitumen, it has a lot of rubber properties, which can only be split or split by hot-pressing. Bituminous rubber is more durable and has a durability in the sun’s rays 2 times more than conventional tires, thus preventing tear, breakage and spraying of rubber.

The advantage of using Gilsonite in Rubber is absorbing Carbon black in entire of the rubber and better mixing with other items those are using for making the Rubber. By using Gilsonite, the quantity of carbon of the rubber would be very higher and the rubber strength against the abrasion would be very higher and the final products would be more natural and costs would very lower.

-

Gilsonite in wood industry

Gilsonite is used as a waterproof cover for wood. The color of the liner is called shapan.

Shapan is essentially the same as a bit of water. It is a kind of wood covering. Shapan is diluted somewhat and is pulled down by the fabric on the surface of the wood. Shalapur oil is also oil and gasoline.

A color and resin base for interior and exterior oil-based penetrating wood stains. Ideal for both smooth and rough-cut wood, Imparts water-proofing properties to protective coatings and enhances the natural wood grain. Excellent weather ability, Resists water, Abrasion, and Discoloration.

Gilsonite adherence ability dues to use in many industries as an additive to increase the adhesion of the material considerably, for example in some countries such as Turkey coal is manufacturers in cubic shapes and to preserve the cubic shape Gilsonite is added to the mixture and acts as a glue to hold the material together.

-

Gilsonite in steel product

Gilsonite is an ingredient in several additives used in the production of steel. It is used in Limestone, Lime, Magnesium, and Calcium Carbide additive systems. The function of these additives is to remove impurities such as sulphur, silica, and phosphorus from the molten steel and move them to the molten slag layer.

Gilsonite fulfils several roles as a component in Steel Making Additives. First, Gilsonite is approximately 75% volatile at 1900°F, and when added to the molten steel it promotes the mixing of the additives so the chemical reactions that will move the impurities to the molten slag layer can take place. Next, the volatiles that are given off are high in lustrous carbon, which will further reduce the Iron Oxide to steel. Although CO reduces most of the Fe3+ by indirect reduction, a portion must be reduced directly by elemental carbon. Finally, the portion of Gilsonite that is not volatilized is a very highly structured asphaltene structure that is nearly pure carbon. This will add carbon content to the steel.

Gilsonite is used as a solidifying agent in metal alloys, this material has a high carbon percentage which creates a reductive environment when added to melted steel. It is also used in other industries, such as aluminium, refractory materials, paints and Furthermore, Gilsonite is used as insulated coatings for pipes.